|

|

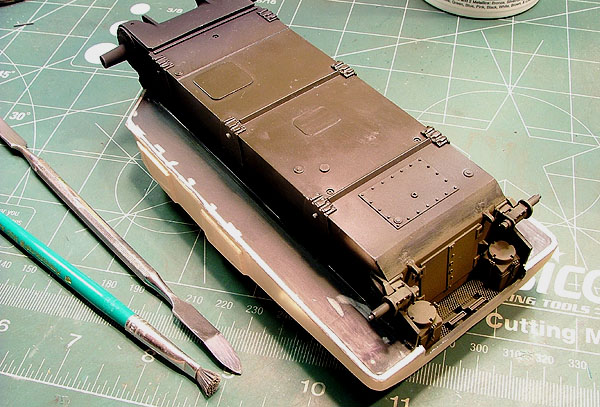

Not

needing to be overly concerned with

neatness, I applied the Apoxie Sculpt

generously to the seams underneath the

sponsons. I had plenty of time to work with

it, so speed wasn't a great concern either.

I let the Apoxie putty setup for a few

minutes and then smoothed out the excess

with a wet finger.

I left

the model alone for about an hour and then

smoothed out the area some more with a

medium grade sanding stick to the finish in

the photo at right.

I

don't mean to rave about either the

Formations Model product or Apoxie Sculpt

too much - but - I enjoyed working with both

on this project quite a bit. I experienced

no problem to complain about, and that's

pretty remarkable for the first time using a

new product.

After

working and sanding the Apoxie Sculpt so

fast, I left it alone to dry overnight -

hoping that I didn't mess up by being too

eager to work with it. To my relief, I

discovered it setup fine the next day. I can

honestly recommend Apoxie Sculpt to novice

modelers used to working with 2-part putty

systems.

Formations Models

Horizontal Return Roller Bracket

Suspension

Quite

pleased with how quickly and cleanly

this conversion project was going, I

moved into putting together the

all-important bogie truck subassemblies.

I still hadn't permanently joined the

two hull halves so that I could continue

handling the model during construction.

In retrospect, they fit together so

snugly (no tape needed to keep them

together once the Transmission Cover was

glued into place) that I didn't need to

be so cautious.

Formations

Models provides the bogie trucks in single

pieces - welcomed by me - with very nice

detail present. These were the only pieces

in my conversion set where I can say I

spent a fair amount of time in cleanup.

Formations' casting is complex and the

cleanup of flash is minor. Dimples are

present representing the mounting points

for the return rollers on the opposite of

the bogie truck - I enhanced these bolt

holes a little more with a few twists of

my pin vise. In cleaning up the return

rollers, it is easy to sand them out of

round profile. Proceed slowly. The return

rollers in my conversion set were out of

round, and I did spend time to get them

back into shape.

It might have been

more expedient to cut them away and use

Italeri rollers instead. I really

appreciated the two piece suspension

parts provided by Formations - but - I

wouldn't have minded getting the return

rollers separately. Three pieces to put

together wouldn't have been bad at all!

Deviating

from the suggested Formations instructions

meant that I did not trap my Road

Wheels/Arms inside the bogie trucks. This

allowed me to paint them separately and

then attach later. To allow the Road

Wheels/Arms to rock like in the original

Italeri kit, I inserted a length of

Evergreen styrene rod (#232 .080" Rod) to

replace the pins in the Italeri parts. The

new rod sits in the cup underneath the

Italeri Volute Spring (Italeri Part #B3)

and is easy to drop into place during the

end assembly before mounting the track

runs. Formations Models resin Track Skids

are thin and pleasing to the eye - and

they provide a couple extras in case you

slip-up during removal from the pour

gates. Slipping them into place neatly

wrapped up modeling the suspension. Of

course, the Italeri "rocking" motion isn't

strictly accurate, the arms on the real

examples move independently, dampened by

one of the vertical volute springs. You

could go all the way here and use AFV

Club's suspension arms to post your tank

treads in action. I was thrilled with my

kit and didn't feel the urge to go that

far.

Before

closing up the Hull, I painted the insides

of the rear hull underside as well as the

tops of the Air Cleaners and Engine Deck

Screen to make sure I got adequate paint

coverage on the dissimilar parts. I made

the Engine Deck Screen by first cutting a

pattern out of 3M Post-it Notes paper and

then used that to trim out brass micromesh

sold by Scale Scenics (#652-3501).

Formations M4A1 Hull with Applique Armor

- Hull Fittings & Little Bits

Take

your time - again - in separating the

thin Fenders from the resin pour gates

and carefully remove the resin flash. I

test fit mine several times to the Hull

to make sure what I was removing in

cleanup was indeed what I was supposed

to be removing.

Formations

Models' conversion kit provides you a nice

length of wire to model the Latch Pins for

the Armored Fuel Caps (Parts #B1). I opted

to use .015" solder instead because I had

a #80 pin vise drill bit handy. Removing

the Armored Fuel Caps from the resin pour

gate wasn't as tricky as I thought it

might prove - but Formations provides

extras in case you mess up along the way.

You only need five for this conversion.

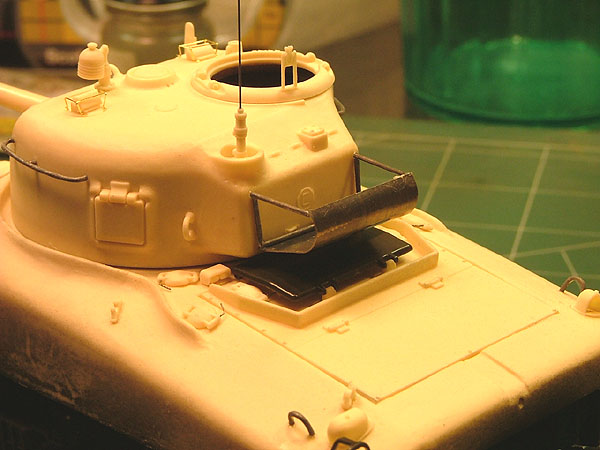

High

on the "cool factor" chart, Formations

also provides you an option to attach

the infamous "Comb Device" (Part #G8) to

your model's Transmission Cover. You

know I couldn't resist! I highly

recommend cleaning up the delicate "Comb

Device" while still attached to the

resin pour gate - and to trim it away

carefully afterwards. I launched mine

high into the stratosphere and

fortunately rescued the piece in the

nick of time before it was lost to the

Carpet Monster forever.

I

cleaned up all the Lift Rings and Tow

Clevises while still on the resin pour

gates successfully before trimming them

away. I drilled out the end of the

.30cal bow Machine Gun Barrel with a #80

bit and then with the point of my X-Acto

Blade. I opened up the Machine Gun's

mount (Formations Part #E6) and

Italeri's Armored Cap with a 1/16" drill

bit to accept the Formations .30cal

Machine Gun Barrel cleanly. Keeping the

1/16" drill bit out, I also cleaned out

the resin flash on the delicate Tow

Cable Clamps (Parts #K4) and inserted

the Tow Cable Eyes (Parts #F4) to make

sure they slid in and out easily.

I

cleaned up a little resin flash from the

Headlights (Parts #F5) with a couple of

twists with a 1/8" drill bit. Formations

Models conversion kit includes two MV

Products Lenses for inserting into the

Headlights in the end assembly. Very nice

touch! With the Tail Lights (Parts #K2)

Formations instructs you to remove the

bottom mounting portion cast into these

parts.

Unfortunately, I trimmed

too much away and didn't feel comfortable

with the result. I super-glued short

lengths of scrap styrene .040" rod to the

Tail Light post and drilled corresponding

holes where they'd eventually locate on

the Upper Hull. These were easy to insert

in the end assembly and set to an

acceptable height. The Siren/Horn (Part

#G2) is cast on the round end of the back.

Trimming it away from the resin pour gate

created an undesirable flat spot. I filled

this spot with a good sized drop of super

glue, dropped a spot of accelerator on the

super glue, and then carefully spun the

Siren/Horn between my fingers against a

sanding stick to restore the blunt,

rounded profile. I sat back and called it

a day.

|