|

Formations

M4 Low Bustle Turret Sub-assembly

I began

my modeling efforts with the Turret. Before I

continue, I must caution you that there are a

fair number of parts in this conversion set.

The resin pour gates are marked with part

number callouts - and it is advisable you have

room to spread some out as you go to make sure

you've got all the parts in the right place

for the step you're working on at that time. I

found it helpful to actually cleanup my

workbench and remove other in-progress models

to make room for this one. I also did not wash

any of the Formations Models resin parts prior

to assembly, nor afterwards. I found them to

be quite clean and free from resin mold

release.

There is

a small pour plug to remove from the hollow

turret shell and the opening for the Mantlet

is easy to cut away with a sharp X-Acto blade.

Working with resin, it is advisable to keep a

supply of new blades handy - they make the

cleanup work easier. To remove the resin pour

plug located underneath the front lip of the

turret casting, I recommend flush sawing with

your 1" saw blade. Several times I caught

myself wanting to snip this away with a pair

of Xuron Cutters, but I was afraid I'd damage

or split the thin casting here. Flush sawing

was definitely the way to proceed here.

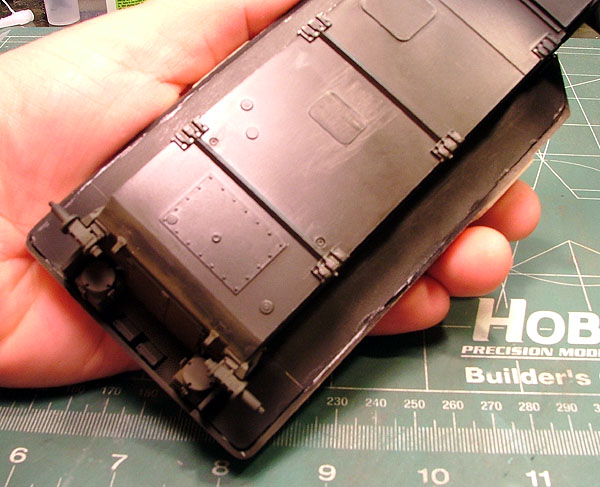

To

deal with the turret race (photo left), I

attached sandpaper to a sheet of glass and

sanded the part down for a good fit. The

turret race in my kit was a little larger than

the circumference of the turret opening.

Flipping the part upside down to sand helped

reduce the diameter of the part. I then

matched the flat end of the turret race to the

corresponding area of the turret bottom

underneath the Mantlet - trimming the areas

around the ring slowly with a sanding stick

until the two parts fit flush. Patience (a

part of the Formations suggested assembly

instructions) pays off dividends in working

with any miniature. I can't emphasize how

important it is to sand slowly and test-fit

frequently when building resin kits. It is

eminently easier to remove small bits of resin

at a time than to try and go back to fill

areas where you too aggressively removed

material.

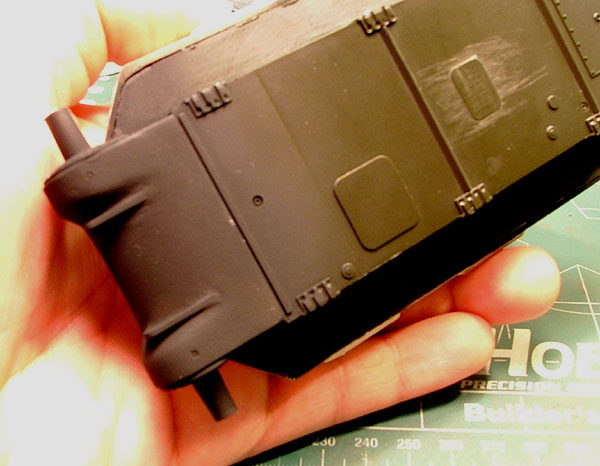

All the

Mantlet/Gun Mount parts fit snugly to the

Turret opening. Follow Formations' suggestion

to leave the flash inside the Lift Rings while

you attach them to the Turret. It is easier to

attach them and then clean up after the glue

sets - lessening the chance of breaking the

delicate parts. I chose to model my Loader's

Periscope in the "up" position (actually - all

of them), so I set Parts #H1 and K1 into place

per the instructions. I decided to not use

Part #F3 (Antenna Mount) as provided in the

conversion set and instead used one of

Formations' US WW II Vehicle Antenna Mounts

and Masts (#F010). I just love these, they

come with the antenna wire cast into the

Mounts - and they are removable for painting

separately. Part #G5 (MG Travel Lock) was

a bit tricky to cleanup, but patience and a

sharp knife helped make this a break-free

step. I found myself referring back to my

completed Tamiya M4 (Re-manufactured) to aid

in placement. The Formations Models

instructions are good, but as I'm not overly

familiar with the Sherman - every additional

bit helps.

Careful

trimming got me the Commander Hatches clean

and ready for addition of small details found

in nicely cast Periscope and Latch parts. I

also fitted the Searchlight provided in the

conversion set. All in all, messing around and

watching TV, it took me an hour to clean up

and assemble the basic turret sub-assembly.

Formations

Models M4A1 Hull with Applique Armor

Moving

on to the Hull, I began by cleaning up all

the odd bumps, sinkholes, and associated

remnants of the Italeri manufacturing

process. Each kit will vary in cleanup

called for, but remember that this is an

oldie - but a goodie. I fitted the Braces

(Parts #L3 and L4) into place underneath the

leading edges of the sponsons as called out

in Formations' instruction sheet. I worked

on the Tom Cable and set it aside as well.

In

cleaning up the resin Upper Hull, I scored

around the Engine and Turret opening with

the sharp X-Acto Blade a few times - then

punched through the center of the thinner

resin flash with the blunt end of my X-Acto

Knife. I braced the Upper Hull piece on my

workbench before doing this. It worked like

a charm - though sounding unorthodox. The

remaining cleanup for the Upper Hull was

easy and quick. I also sanded the bottom of

the Upper Hull with sandpaper attached to a

glass board for good measure - though my

casting was clean and air bubble free.

In

test fitting to the Italeri Lower Hull pan,

I opened up the flashed-over notches in the

nose of the Formations Upper Hull piece for

a better fit. Skipping ahead in the assembly

sequence, I attached the Sponson Plates

(Italeri Parts #A17 & A18) to the Lower

Hull Pan. I wanted to test-fit the joining

of the two Hull halves quickly. You will

have to trim back the Italeri plates a

little to fit the Formations Upper Hull

properly. Just work slowly and trim back a

little at a time until you set the two

pieces together properly. I used a Miter

Cutting (Chopper) tool to trim back the

Italeri parts until they fit. I glued them

into place with Model Master Liquid Cement

and then joined the two Hull halves so that

the parts could setup in place overnight.

The next day I would address the joint with

Gunze Sangyo Mr. Dissolved Putty and

subsequently sand the joint clean. Letting

the Hull halves setup overnight is a good

opportunity to cleanup the rest of the small

Hull fittings. In resin, this proved

considerably less of a time-intensive chore

than it would have been for the

corresponding plastic Italeri parts.

The

next day, I proceed to trim away the flash

at the rear of the Formations Upper Hull

covering the characteristic "notch" present

on the actual Hull casting. I went to fit

the solid resin Transmission Cover and

Engine Deck pieces quickly afterwards. The

Formations Models instruction booklet

doesn't cover fitting these parts, but I

found this task virtually a no-brainer -

they just slide into place. Test fitting

revealed that indeed a small amount of putty

is called for at the joint between the Upper

Hull and Transmission Cover - as mentioned

in the Formations instruction sheet. For

this, I found the Apoxie Sculpt ideal to

work with.

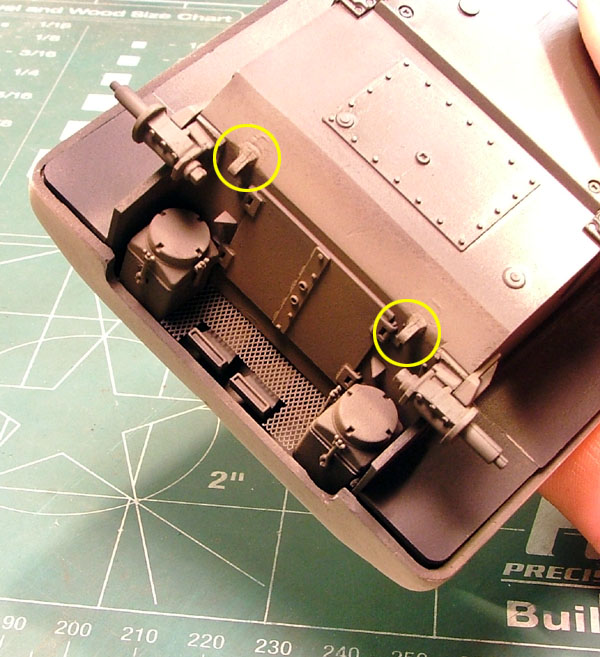

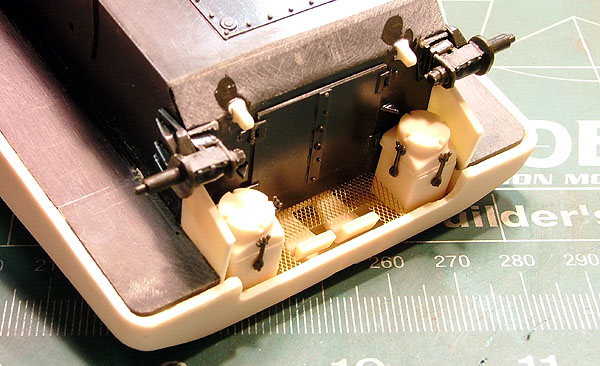

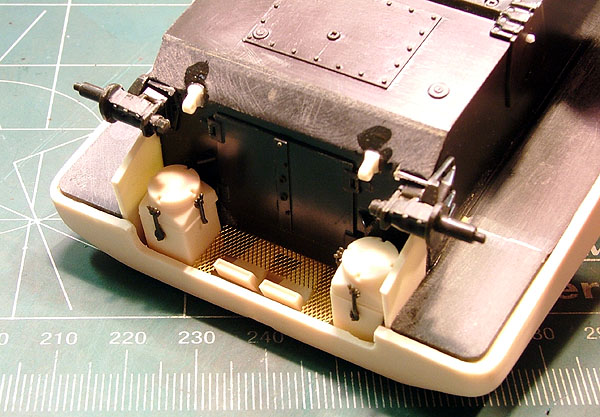

I then

proceeded to fit the Formations parts found

underneath the Real Hull overhang. I held off

on permanently joining the Upper and Lower

Hull halves until I got these pieces into

place properly, taping them together instead.

Formations

indicates that you may find that you have to

trim down the tops of the Air Cleaners (Parts

#D4 & D5) to get the Upper Hull and Lower

Hull to fit correctly. I adjusted the height

of fitting the Exhausts (Parts #D6) to the

Italeri Rear Hull Panel because I felt they

sat too low - sticking out too far below the

Formations Upper Hull Notch - during test

fitting. Then, I set the two "wings" (Parts

#J3 & J4) into place, mounting to the left

and right sides of the Rear Hull, and used

them to line up the Air Cleaners (Parts #D1,

D4, & D5). The fit is so tight that there

was no need to glue the "wings" into place as

I eyeballed the Air Cleaners into their

spaces.

I

did trim away the innermost nubs on the

Italeri Rear Hull panel to better accept the

Formations resin Air Cleaners - their mount

stubs are slightly wider than the

corresponding gaps on the Italeri part.

Formations instruction sheet shows the "wings"

as notched at the bottom to clear the mount

for the Idler Wheel - but my parts were not.

Simple to perform, I just cut quick notches

with my X-Acto Knife and moved on. Lastly, in

this area, I fashioned the Screen that the

Exhausts pass through underneath the Rear Hull

overhang using scrap photoetch parts.

With

all the major sub-assemblies completed, I

proceeded join the Hull halves. They fit so

well together that I felt comfortable using

5-minute epoxy for the bond. This provides

both strength and some setting time to get the

two halves together and adjust if necessary.

Don't you hate it when you've test fitted two

parts together several times, only to then "go

to the super glue" and not get that perfect

alignment? Murphy's Law in action. The

5-minute epoxy gives you some time to make

sure things line up. Before proceeding, I

allowed the model to setup overnight.

Joining

the Hull halves was uneventful the following

day. The 5-minute epoxy went on first for

strength and some gap filling around the

sponson joints - leaving little to fill in

the end. This proved to be a plus. Next, I

applied the Apoxie Sculpt as a filler to

eliminate the left over seams between the

Italeri and formations Models Hull halves. I

found the Apoxie Sculpt the best 2-part

putty I've work with in modeling to date. It

is simple to work with, soft and won't cramp

your fingers like Milliput can while mixing

and working. Wearing gloves is optional -

and I tested that with this model. I worked

it with no skin irritation and kept a little

water on hand to prevent it from sticking to

my palms and fingers. I only used a pinch of

each tin and rolled them together. Apoxie

Sculpt gives you from 1 to 3 hours working

time - but I puttied the joint between the

Transmission Cover and the Upper Hull as

well as both sides underneath the sponsons

in about 15 minutes.

|

I noticed a slight bend in my

75mm Gun Barrel, but it wound up being not

that noticeable in the end assembly. I trimmed

it away from its pour gate and cleaned up the

end with a few swipes of the sanding stick.

Then, I heated the part in hot water (not

boiling) and rolled it on a glass sheet to

take out the slight bend. It fit into its

rotor (Part #N2) without any problems, and

there is a little slack to allow you to adjust

the barrel's fit.

|