|

Setting

the Stage for Construction & Detailing

When I

opened the model kit box - I had no clue to

as how I wanted to finish it, other than

wanting to model an accurate Operation Cobra

era M4A1(76)W Medium Tank. I read through

George Winter's book a couple of times and

dug up as much information as I could on

that Sherman tank variant. I asked for some

information/advice from noted Sherman tank

researcher Kurt Laughlin to fill in some

unanswered holes too.

My

recipe for modeling Graham's "D-32"

M4A1(76)W was based on all the information I

gleaned from above:

Registration

Number: None, as these appear to have been

painted out/over in photos of this unit's

tanks at that time.

Camouflage

Pattern: Black over Olive Drab. I did not

put the chrome yellow Invasion Codes on the

turret sides, as they were generally

painted-out by this time of the war. I also

didn't "fresh-patch" the paint over where

they might have been placed either. This was

a coin toss decision, on one hand the

"fresh-patch" of paint is quite reasonable

and a common occurrence. On the other hand,

I thought that by December 24th, the crew

might have touched up the turret a little

finer than that, and went with this option.

National

Symbols: I went with US National Symbols on

the engine deck and turret roof, unbroken

rings.

Organizational

Codes: I placed these in their common

locations on the Hull, though they are

obscured by accumulated mud/dirt in the end

finish - the same as the photographed tanks

appear in the book.

Gun

Barrel: I surmised that "D-32" was one of

the initial batch of 102 M4A1(76)W delivered

to the 2nd and 3rd Armored Divisions in the

ETO, I went with M1A1 76mm Gun fit without

muzzle brake or thread protector.

Turret

and Hull: In keeping with the above thought,

consulting with Kurt Laughlin about these

vehicles, I chose to model a vehicle coming

from Pressed Steel Car Company - as they

produced this batch of Shermans delivered to

the ETO.

Pressed

Steel Car Company was an assembler of

components, not appearing to have their own

foundry for large casting of Sherman parts.

Continental Foundry produced the cast hull,

with no currently known external casting or

foundry markings. The Dragon Models kit

doesn't have any either - making this a

fortuitous choice.

Though

the Dragon Models kit turret has casting

markings present on their part, accurate for

an example on display in Bastogne, it is not

accurate for the turret casting used by

Pressed Steel Car Company. They were

provided turrets by Union Steel Company -

with uncharacteristically large casting

numbers on the turret flanks, and more

traditional ordnance numbers on the turret

roof ahead of the crew hatches. Kurt

provided me with photos of these numbers,

and I need them to get the courage to put

them on my kit part - they are so unusual I

felt no one but Kurt or Rob Ervin of

Formations Models would even know what they

represented if I took the model to a show.

Tracks:

I selected the T-48 Rubber Chevron Tracks

seen to be worn by the unit's tanks in

photos, but didn't chose the shorter

extended end connectors seen on other tanks.

Since "D-32" isn't capture in photos, I

surmised it could have worn the longer ones

I eventually went with.

Running

Gear: Solid Drive Sprocket Plates and

Solid-Spoke Road Wheels/Idler Wheels, would

be my choice - though it could have been a

combination of types. Since Dragon Models

did not include an option for backside

inserts on their Solid-Spoke Idler Wheels in

this model kit release, I used a resin set

from Formations Models.

Construction

& Detailing

I

wanted to follow Dragon Models' recommended

assembly sequence as closely as possible

along the way for detailing and corrections.

I started out wanting to build the kit as a

review subject, goal being to use as many,

if not all, the kit-provided parts during

construction. I did stick to this goal for

the most part, but couldn't help violating

it in a few instances.

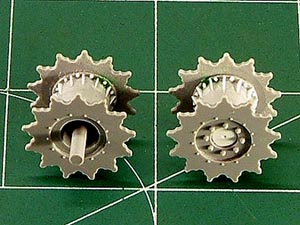

Step

One: The first pieces trimmed from the sprue

trees were parts to make up the simple-plate

Drive Sprockets. There were shallow, and

easy to remove, ejector pin marks on the

inside faces of these parts (D15). There is

no positive mating between the Sprocket

Plates and the Drum, prompting me to use

several track links to line up the Sprocket

Teeth properly while the parts set. There

were some minor gaps that needed to be

filled with putty afterwards.

On the

backsides, the Dragon Models parts are not

detailed, missing plate screws and support

ribbing that I added using scrap styrene rod

and strip.

Moving

on, I really appreciated Dragon Models

inclusion of backside inserts for the

Solid-Spoke Road Wheels in this model kit.

They fit together tightly, but do result in

a small gap to fill around the

circumference. In working on this step, I

borrowed a tip from fellow Sherman modeler

Laramie Wright and trimmed back the mounting

axles on the Suspension Arms (Parts V1 and

V2) for the Road Wheels. This allows you to

put the Road Wheels in place after

assembling the Bogie Units, and keep them

separate for painting - while being able to

deal with that annoying seam to deal with

while putting the Bogie Units together. If

you are into chunking-up the rubber on your

Road Wheels, his idea makes it easier to

accomplish and add to your Bogie Units

later.

For

all the effort put into detailing the Dragon

Models kit, there is still missing detail on

the Solid-Spoke Road Wheels - principally

288 missing rivet heads around the

circumference front and back. If Dragon

Models would have included this detail on

their parts, I think I might have raved on

half a webpage about how great that was.

Is

this detail omission noticeable in the end

product? Yes. I would have gladly traded

some of the kit-provided optional photoetch,

plastic spares or brass 76mm rounds to have

gotten this detail. I wound up devoting

about three and a half hours adding these

rivet heads to my Road Wheels using Grandt

Line #153 items.

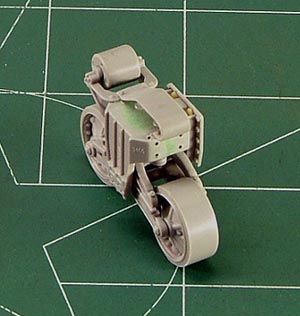

Step

Two: The Bogie Units come together in this

assembly sequence, with Dragon Models' parts

decently rendered in scale and some nifty

casting numbers in place. I would have

really liked to see the Suspension Arms and

Levers cast independently in this kit

release, though. The kit parts as presented

allow for some articulation, a "rocker"

motion, but not truly faithful to the actual

Road Wheel travel in the real Sherman.

Coupled with Dragon Models' individual track

links, the modeler could convincingly model

their kit over uneven terrain easier.

To be

fair, I did take advantage of the "rocker"

motion offered in the Dragon Models kit when

it came to assembling the individual track

link runs. I was able to set the track runs

in place on the model to dry overnight, and

remove them for separate painting and

weathering, by just being able to move the

#1 Road Wheel up and out of the way while

working with them.

I

assembled the Bogie Units, trimmed back the

axles for the Road Wheels and then putting

the resulting seams before drilling and

adding missing bolt details. I'm often left

wondering if a manufacturer will ever

present modelers with a Bogie Unit that is

cast with the entire front as a single-piece

and a simple backside insert, to eliminate

that annoying seam to remove in present kit

parts.

Bogie

Units used on the M4 series of Medium Tanks

are symmetrical, with Skids and Return

Roller Supports capable of being mounted on

either end - to make the suspension assembly

usable on either side of the tank. Sherman

modelers commonly have to drill out the bolt

holes opposite the Return Roller Mounts

whenever they put a Sherman kit together.

Nothing different in this kit release. I

also drilled out the corresponding holes on

top of the housing, opposite the front of

the Skids. I added two Grandt Line bolt

heads to represent the anchors for the

Vertical Springs, found underneath the

Skids. This detail should be countersunk,

however, I made mine raised in haste to move

forward in construction.

I felt

no need to replace Dragon Models Skids

(Parts V6), though there are thinner

aftermarket replacement available. I just

thinned the outer edges with the back of an

#11 X-Acto Knife Blade to reduce the visible

thickness. When done, I added four bolt

heads to them and glued them on the housing.

I mentioned above that I added two more

bolts on the Mounting Plate (Part V5) missed

by Dragon Models, but admit I probably did

so because I got so giddy in adding all the

extra stuff. I heartily doubt anyone would

notice them in the end product. I wound up

adding 108 more bolts and rivet heads than

another, perhaps sane, modeler would -

likely for nothing other than personal

satisfaction .

But -

that is what modeling is all about after

all. Don't let past experiences with AMS

psyche you out of going nuts on your

modeling project. If you are having fun,

then go for it! As long as it is kept in

perspective, you'll be fine.

Steps

Three, Four and Five: As called out on the

Instruction Sheet, I drilled out the

locating holes in the Rear Panel (Part H6)

with a 1.5mm drill bit. In my kit, the fit

between the Rear Panel and the lower Hull

Pan (Part Z) called for some filler putty

above and below the locations for Parts D26

& D27, and some to clean up the bottom

joint. Heck, simply thankful to have sponson

floors included in my kit from Dragon

Models, I didn't blink twice when it came to

a little trimming and seam puttying. When it

came to attaching Parts H8 and H9 to the

sponson floors, I must have misunderstood

the Instruction Sheet., and put the large

locating tabs on the outside of the Hull.

This called for later cutting away and

puttying to eliminate the joint.

Though

I commended Dragon Models for their

inclusion of backside inserts for the

Solid-Spoke Road Wheels in this kit, I was

mystified as to why there were no

corresponding inserts for the open backs of

their Solid Spoke Idler Wheels. I used a

replacement set from Formations Models. The

only detail I added to them was a set of

.005-inch styrene rings to the front and

backs of both Idler Wheels, the detail

easily seen on the real examples, but I've

never seen included on kit parts before.

Probably would be a bear to attempt to cast.

Anyway, after going overboard with bolts and

rivet heads, four rings seemed to be an

understatement.

I

experienced difficulty when attempting to

attach the Idler Wheel Mounts (Parts D26

& D27) in proper position - mine wanted

to set skewed out of alignment. I wound up

cutting the locating pins away to do so. I

do not know if this is a known problem with

the kit parts in this area. Everything else

in the assembly step fell into place without

fuss.

|

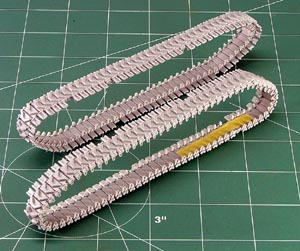

I

spent a little more than 14 hours putting

together the Dragon Models tracks included

in the kit. It took a long time and a lot of

coaxing and gently play to get them

together. I fussed all the way too,

admittedly. This was the first time I've

ever given them a go, and didn't want to

give up on them. I found that patience does

pay off, and I could actually fit them onto

my model tank's suspension to setup

overnight. In the photos shown above and

below, I left off the end connectors where

the Tamiya Masking Tape holds the ends of

the track run together. At this brake in the

track runs, I was able to slip them on and

off the model tank suspension easily, and

could paint and finish them separately until

it came time to join them permanently in the

end assembly stage. Pretty good for never

having worked with Dragon Models individual

link tracks before...

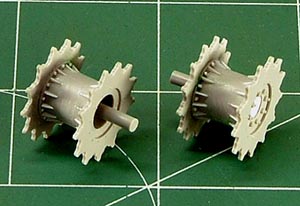

Above

and below, forgive the contrasty images, I

wanted to add some more detail to Dragon

Models' Drive Sprockets that isn't easily

seen otherwise. the stiffeners and bolt

heads are just scrap styrene stock -

time-consuming to put in place, but I wasn't

in a hurry to finish the model miniature

anyway. It adds depth of detail to match the

rest of the nice detail already present on

the model kit - and does go a bit unnoticed

in the end. I figured if someone took the

time to look, I might be served well to give

them something to look at.

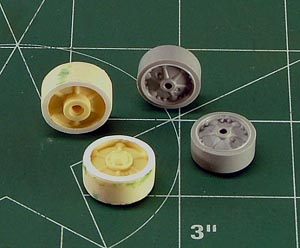

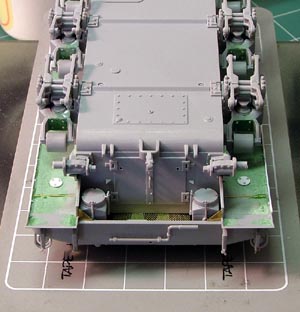

Typical

Bogie Unit with additional bolt and rivet

head details all around. Dressed up, the

Dragon Models parts look handsome. Below, a

couple of Road Wheels with rivet heads in

place front and back sides. Also, Formations

Models Idler Wheels with added Rings front

and back sides trimmed out from .005-inch

styrene stock.

The

joint between upper and lower hulls in my

kit example called for some putty, in this

case the annoyingly-shrinkable Squadron

Green stuff. Since it is underneath the

sponson floors, and not easily seen, it

works. Above, I added a couple of missing

bolts to the mounting plates for the Bogie

Units. This detail, too, goes virtually

unnoticed in the final miniature - unless

you know what and where you are looking.

Lower photo, I added the Drainage Plates and

tried out the brass etch weld beads from

Aber for the first time. I am not sure what

I think of the final result of using them,

but underneath the sponson floors, they

don't get noticed anyway. Same goes for the

brass mesh screen at the exhausts, which

will go unnoticed once the deflector is in

place. The rest of the detail bolts on the

Bogie Units and Transmission Cover are

standard for Sherman modeling, surprising

that they still aren't there in a kit as

advanced as the Dragon Models effort.

The

Fenders included in the Dragon Model kit

were incorrect for the variant I wanted to

model. So, instead of buying an aftermarket

set, I just glued the kit parts in place,

sanded away all the detail and trimmed out

the right shapes. I thinned the underside

edges with a sharp #11 X-Acto Blade to

reduce the visible thickness and replaced

the proper details by scribing and adding

scrap styrene braces and Grandt Line rivet

heads. Traditional modeling techniques still

come in quite handy, no matter how

sophisticated the kit manufacturing process

becomes.

When it

came to attaching the Transmission

Cover, I wound up filling the joint all

around. It seems cast too short to reach

the upper Hull properly, though it was

not difficult to fill. I think in the

future I'd probably lengthen the part a

little - and figure out how to match the

cast texture rendered by Dragon Models.

Speaking of that, I appreciated the

texture cast by Dragon Models. I thought

it would look nice under thin coats of

paint, and wasn't disappointed in the end.

But, such a detail is something that one

modeler will like, and another won't. To

each his own. I added Drain Plugs to my

Transmission Cover, as well as a Comb

Device and two tie-downs. I did not add

foundry or casting numbers to my kit part,

however, because I didn't feel comfortable

with the type used by that batch of 76's

sent to the ETO. I settled on a thin coat

of accumulated dirt/mud in that area -

reasonable for 24 December, 1944.

|