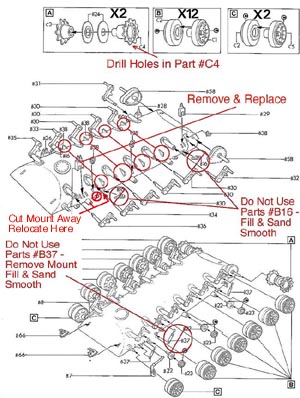

|

| In

an attempt to help illustrate my

recommended modifications and

additions to the basic ESCI/ERTL/AMT

model kit Hull, I annotated my notes

on scans of the Assembly Sheet. |

| The

ESCI/ERTL/AMT Hull is the best

1:35th scale rendition presently

available - and what I personallt

feel is the best foundation for the

M60 MBT conversion. The

modifications and corrections needed

to make it more faithful to the

actual M60 MBT are few and easy to

accomplish. The most visible of the

modifications called for come in

eliminating the second Shock

Absorber on each side, replacing the

molded-in Suspension Stops and

relocation of the forward Return

Roller - moved back towards the rear

- as all three are evenly spaced

apart. Less visible is trimming away

the hull mount for the Idler

Adjustment Arm and creating a simple

bracket to attach it to the #1

Suspension Arm. |

| The

AFV Club/Academy Commander's Cupola

is one of two 1:35th scale

subassemblies that I know of

presently available. The other is an

item produced by Tank Workshop - but

I haven't seen it. The above

injection-molded plastic item has a

very nice, subtle, texture and

casting numbers present on the

Cupola roof. The white piece of

styrene sheet represents the Mount

Plate for a pedestal mounted .50cal

MG seen on the M60 MBT during the

period when there were probems with

the M85 .50cal MG in the Commander's

Cupola. I modeled this feature along

with the rear turret mount provided

by CMD and a barrel clamp liberated

from a Italeri M47 Patton that was

positioned on the turret roof. |

Chesapeake Model Designs'

(Early) M60 Turret and AFV Club

Commander's Cupola & Xenon Searchlight

First off, there is no such

thing as an "early" and "late" M60 Turret.

CMD points out in their instruction sheet

that they used the term to make it clearer

to the modeler that this turret is only

appropriate for the M60 MBT - and not the

later M60A1, A2 or A3 variants - in case

you're unaware of the difference.

Designed for the

ESCI/ERTL/AMT model kits, the CMD M60 Turret

is pretty complete as it comes in the box. I

used Gunze Sangyo Mr. Surfacer 500 to patch

and texture the joint between the upper and

lower halves of the Turret. The real M60

Turrets are not rough in this area, and the

Mr. Surfacer fills but does not obscure the

fine CMD cast detail.

The resin parts are thin

and cleanly cast, with little to no cleanup

issues to mention in my example. CMD's

instructions are simple, with an exploded

drawing diagram. I recommend reading them

several times until you understand how to

proceed in completing the subassembly

though.

A fine turned aluminum

barrel is included to represent the M68

105mm Gun. I admit I didn't quite understand

how to attach the accordion-like Dust Cover

to the Mantlet Cover and had to resort to

in-service photos. I sanded and set an angle

for the part that I liked in the end. CMD

instructions call for you to locate the Gun

Barrel end a scale 13 feet from the Mantlet

Cover. My 1:35th scale rulers are as welcome

as my X-Acto Knife - proving quite handy for

this purpose.

I snipped off the cast-in

handle for the Loader's Hatch and added one

made from a length of .022" solder. You

could also go as far as replacing the Hatch

Springs too - but I opted not to. I liked

the detail already present. The CMD Turret

had preset holes for the Stowage Handles on

either side, but I found that none of the

plastic parts I had fit these locations. No

problem, I fashioned my own Stowage Handles

using .022" soldier.

This sounds

like a difficult medium to work with, but

really isn't. When finished, the solder

parts are strong - you just have to be

careful in handling so as not to bend them

out of shape. You shouldn't paw your

precious miniatures anyway! I first inserted

lengths of solder into the holes, and set

them in place with super glue and

accelerator. I trimmed them all to the same

length. Then, I cut a length of solder and

attached it to each leg with a drop of super

glue and accelerator to hold it in position.

It took only a few minutes and looks nice in

place. This sounds

like a difficult medium to work with, but

really isn't. When finished, the solder

parts are strong - you just have to be

careful in handling so as not to bend them

out of shape. You shouldn't paw your

precious miniatures anyway! I first inserted

lengths of solder into the holes, and set

them in place with super glue and

accelerator. I trimmed them all to the same

length. Then, I cut a length of solder and

attached it to each leg with a drop of super

glue and accelerator to hold it in position.

It took only a few minutes and looks nice in

place.

The Turret

Bustle is also done with .022" solder - as

is the rod welded along the rear bottom edge

seen at left and below. CMD provides you

with a neat jig to set the Bustle Rack

braces in place properly - assuring you that

they were not always symmetrical on the real

M60. Once the braces were glued into place

with super glue and accelerator, I went back

and added the lengths of solder. Working

slowly, the Bustle Rack came together

without a problem. I made the bracing strips

out of lengths of .010" foil - again using

patience, superglue and accelerator. The Turret

Bustle is also done with .022" solder - as

is the rod welded along the rear bottom edge

seen at left and below. CMD provides you

with a neat jig to set the Bustle Rack

braces in place properly - assuring you that

they were not always symmetrical on the real

M60. Once the braces were glued into place

with super glue and accelerator, I went back

and added the lengths of solder. Working

slowly, the Bustle Rack came together

without a problem. I made the bracing strips

out of lengths of .010" foil - again using

patience, superglue and accelerator.

Both

Antennas are made from lengths of .015"

brass wire. I originally attempted to model

the antennae with .022" solder, but this

proved too flimsy for application. It was

just too nerve-wracking to have to watch out

for the solder everytime I handled the

model. Both

Antennas are made from lengths of .015"

brass wire. I originally attempted to model

the antennae with .022" solder, but this

proved too flimsy for application. It was

just too nerve-wracking to have to watch out

for the solder everytime I handled the

model.

The Power

Cable for the Xenon Searchlight is a length

of .050" rosin core solder. The Xenon

Searchlight Unit I used comes from the AFV

Club M48H model kit - as I liked the detail

better. The "face" of the searchlight was

detailed with Grandt Line bolts (Note that

the photos show screws on the face), and the

inside of the unit was done with aluminum

foil super glued to .020" lead foil. The Power

Cable for the Xenon Searchlight is a length

of .050" rosin core solder. The Xenon

Searchlight Unit I used comes from the AFV

Club M48H model kit - as I liked the detail

better. The "face" of the searchlight was

detailed with Grandt Line bolts (Note that

the photos show screws on the face), and the

inside of the unit was done with aluminum

foil super glued to .020" lead foil.

The lead

foil is easy to cut into shape and bend into

an insertable reflector housing in which you

can insert the "bulb". I had to trim out my

own "glass" face for the Searchlight, and a

mask to protect the finished interior during

painting and finishing the exterior. The

small thumbnails below are links to

additional photos of the mount itself -

rather confusing in the model kit(s).

Clicking on the thumbnail provides a larger

photo. The lead

foil is easy to cut into shape and bend into

an insertable reflector housing in which you

can insert the "bulb". I had to trim out my

own "glass" face for the Searchlight, and a

mask to protect the finished interior during

painting and finishing the exterior. The

small thumbnails below are links to

additional photos of the mount itself -

rather confusing in the model kit(s).

Clicking on the thumbnail provides a larger

photo.

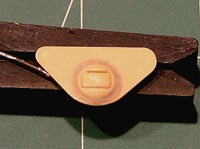

I also

liberated the Commander's Cupola from the

AFV Club (Academy) model kit because I liked

the detail better. To this, I added the

Hatch from an ESCI/ERTL/AMT M60A3 and the

Sight Housing from the M60A1 base kit I was

using. To this subassembly, I added the

mounting plate for the Pintle that mounted

on the early M60 tanks, and drilled out the

four bolt locations on the corners. This

subassembly does not fit tightly in the CMD

Turret as it was not intended to mount on

this aftermarket item, so I had to add

little locator stubs underneath to keep it

seated and aligned properly on the Turret

roof. The right edge of the Cupola locates

49 inches off the tank's centerline. I also

liberated the Commander's Cupola from the

AFV Club (Academy) model kit because I liked

the detail better. To this, I added the

Hatch from an ESCI/ERTL/AMT M60A3 and the

Sight Housing from the M60A1 base kit I was

using. To this subassembly, I added the

mounting plate for the Pintle that mounted

on the early M60 tanks, and drilled out the

four bolt locations on the corners. This

subassembly does not fit tightly in the CMD

Turret as it was not intended to mount on

this aftermarket item, so I had to add

little locator stubs underneath to keep it

seated and aligned properly on the Turret

roof. The right edge of the Cupola locates

49 inches off the tank's centerline.

I provided

a couple of photos of the area underneath

the .50cal Mantlet for you next. It is open

on the kit parts. I hope my accompanying

photos help you if you wish to add detail in

this area. I provided

a couple of photos of the area underneath

the .50cal Mantlet for you next. It is open

on the kit parts. I hope my accompanying

photos help you if you wish to add detail in

this area.

AFV Club

model kit Rangefinder blisters and Lift

Rings were added to the Turret - as CMD does

not provide these in their kit. I added an

Italeri .50cal MG Stowage Clip, and two

Guards from other ESCI/ERTL/AMT M60 kits

that were mounted to protect the Xenon

Searchlight when mounted for operation and

when stowed on the side of the Turret. Not

all M60 tanks show these fitted, as they

were removed by the crews. Another length of

embroidery thread mimics the chain/pin

detail on the Guard in front of the

Commander's Cupola, and for the Cap on the

.50cal MG Mount on the Turret Rear. AFV Club

model kit Rangefinder blisters and Lift

Rings were added to the Turret - as CMD does

not provide these in their kit. I added an

Italeri .50cal MG Stowage Clip, and two

Guards from other ESCI/ERTL/AMT M60 kits

that were mounted to protect the Xenon

Searchlight when mounted for operation and

when stowed on the side of the Turret. Not

all M60 tanks show these fitted, as they

were removed by the crews. Another length of

embroidery thread mimics the chain/pin

detail on the Guard in front of the

Commander's Cupola, and for the Cap on the

.50cal MG Mount on the Turret Rear.

An Accurate Armour Jerry

Can Holder and Aber tie-downs were added to

their appropriate locations on the Turret -

one behind the Jerry Can and nine on the

rear right upper area at the Bustle Rack. I

used a set of Formations Models Tow Cables

to round out the Turret details.

I added more details to the

Turret Roof of my miniature appropriate to

the early M60 MBT's in accordance with the

photos here. These were provided through the

kind assistance of Joe Daneri.  This photo

shows good detail of the mounting plate for

the .50cal MG on the side of the Commander's

Cupola, the Stowage Clip for the .50cal MG

Barrel on the Turret Roof (next to the Guard

to prevent the Cupola MG from firing into

the Xenon Searchlight when stowed) and the

Mount for the .50cal MG on the rear wall of

the Turret. The Mount for the rear Turret

wall is provided in the CMD Conversion - but

I capped it off. The Cupola Mount Plate,

Spring Clip and Guard are details you'll

have to add yourself. I described my sources

in the rest of the text on these pages. This photo

shows good detail of the mounting plate for

the .50cal MG on the side of the Commander's

Cupola, the Stowage Clip for the .50cal MG

Barrel on the Turret Roof (next to the Guard

to prevent the Cupola MG from firing into

the Xenon Searchlight when stowed) and the

Mount for the .50cal MG on the rear wall of

the Turret. The Mount for the rear Turret

wall is provided in the CMD Conversion - but

I capped it off. The Cupola Mount Plate,

Spring Clip and Guard are details you'll

have to add yourself. I described my sources

in the rest of the text on these pages.

Lastly, in

measuring the real vehicle, I noted that

there is a half-inch gap between the Turret

and the Race that is visible from casual

viewing distances - and would be noticable

in 1:35th scale. The gap was wide enough to

be able to see the turret seals for fording

streams. I added small lengths of .015"

styrene strip to unseen areas beneath the

CMD Turret to elevate it. This is a very

small improvment, but one that I liked and

was easy to do. Lastly, in

measuring the real vehicle, I noted that

there is a half-inch gap between the Turret

and the Race that is visible from casual

viewing distances - and would be noticable

in 1:35th scale. The gap was wide enough to

be able to see the turret seals for fording

streams. I added small lengths of .015"

styrene strip to unseen areas beneath the

CMD Turret to elevate it. This is a very

small improvment, but one that I liked and

was easy to do.

Backdating and Improving

the ESCI/ERTL/AMT Model Kit Hull

Consulting photos of

restored M60 main battle tanks, coupled with

the Technical Manuals on the M60 Series, I

set out to make the necessary modifications

to the base ESCI/ERTL/AMT M60A1 kit parts to

model a M60 Hull.

I followed the suggested

assembly sequence and made my modifications

along the way. The ESCI/ERTL/AMT model kits

are the best renditions of the M60 series

tanks in 1:35th scale currently available -

and this made working on my conversion that

much more enjoyable. I experienced no

serious problem during assembly to warn you

about - encouraging further exploration of

the particulars of the conversion. There

were ejector pin marks, sinkholes and some

minor flash to remove from the parts in my

model kit - none too difficult to deal with.

On the positive side, the parts sport nice

texture for the cast areas of the Hull and

Turret, including casting/foundry markings

and numbers. These being noteworthy detail

additions for their time. I annotated the

Instruction Sheet at left for modifications

and changes I made to my model kit - all but

one hidden by the angle of the drawing. All

the modifications are mentioned in the text

and photos to follow however.

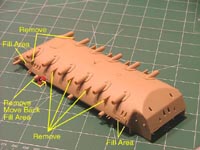

My kit's Upper Hull was

cleanly cast, with some minor filling called

for on the sides of the Storage Bins. I

filled them with super glue and accelerator.

There were no annoying morotization holes to

fill in the lower hull pan. The three major

pieces that make up the Hull went together

without a problem. I filled the joints and

minor gaps with Gunze Sangyo Mr. Hobby brand

Mr. White Putty.

|

Wanting to

keep my final finish and weathering light, I

applied Liquitex Acrylic Light Modeling Paste

to the undersides of the sponsons and Hull

sides. I applied the Paste with a scrap paint

brush and let it setup for a few minutes.

Then, I went back over and textured the areas

with a portion of a Sea Sponge. This works

great for subtely simulating accumulation of

dirt and mud without going overboard.

Though very

similiar to the M60A1, the Hull of the M60

differs in numbers and locations of certain

fittings. The ESCI/ERTL/AMT model kit's

bulges running along the side of the lower

Hull have notches cast into them that I

could not find on the actual M60 tank. I

filled these gaps with super glue and

accelerator. Though very

similiar to the M60A1, the Hull of the M60

differs in numbers and locations of certain

fittings. The ESCI/ERTL/AMT model kit's

bulges running along the side of the lower

Hull have notches cast into them that I

could not find on the actual M60 tank. I

filled these gaps with super glue and

accelerator.

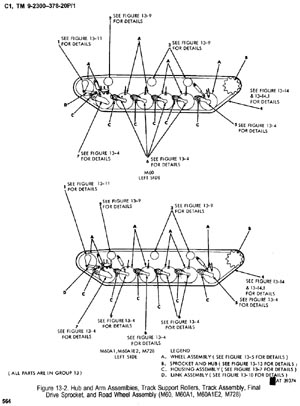

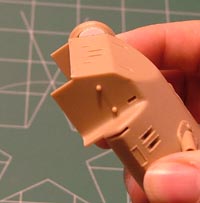

The

M60's #2 Road Wheel does not have Shock

Absorbers - so I removed the mounting points

and restored the cast texture in this area.

I also deleted the Lift Rings (not shown

here in the above Technical Manual drawing)

from the M60A1 model kit, and filled the

locating depressions. The area underneath

the sponsons of the M60 are relatively clean

and neat and these two large lift rings are

not present on the M60 Hull.

I

fashioned replacement Suspension Arm Stops

(for lack of the proper term) and cut away

the simple castings on the ESCI/ERTL/AMT

Hull bottom - which bore little resemblance

to the items on the real M60. The backsides

of all the Suspension Arms need to be filled

as well.

Contrary

to the TM drawing above, the M60's Return

Rollers were evenly spaced apart - with the

front Return Roller only moved forward to

the position shown above in the M60A1 and

later vehicles when the second Shock

Absorber was added. I cut the mounts away

and replaced them with scrap styrene tubing

- relocating the mounts 14 scale inches to

the rear.

Left Above

and Below, I made the replacement Stops

using .030" styrene strip, cut to shape.

Using the Road Wheels temporarily tacked

into position, I glued the stops into place

and simulated the weld beads with acrylic

gel medium. Left Above

and Below, I made the replacement Stops

using .030" styrene strip, cut to shape.

Using the Road Wheels temporarily tacked

into position, I glued the stops into place

and simulated the weld beads with acrylic

gel medium.

Another

view of the actual Stops on the M60 Hull,

along with Return Roller and Road Wheel

detail. Another

view of the actual Stops on the M60 Hull,

along with Return Roller and Road Wheel

detail.

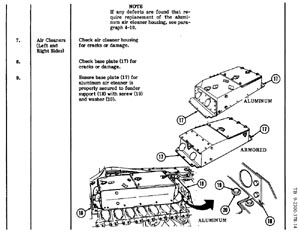

The

M60 was fitted initially with side-loading

air cleaners. At left, the early and late

model side-loading air cleaner styles are

shown. I went with the early side-loader as

provided in the ESCI/ERTL/AMT model kit.

The

attachments for the Shock Absorbers to the

Suspension Arms are a bit simplified and not

100% accurate in the ESCI/ERTL/AMT model kit

- but at least they're present.

Other M60 series kits lack

this feature. The backs of the Suspension

Arms could use additional detail in the

form of caps to close off the open ends

behind the Road Wheel axles at the least.

Part #B37 (Idler Wheel Damper) does not

locate into the Hull, as molded in the

ESCI/ERTL/AMT model kit.. Trim and fill

this locator away - and attach the Damper

to the Suspension Arm. Other M60 series kits lack

this feature. The backs of the Suspension

Arms could use additional detail in the

form of caps to close off the open ends

behind the Road Wheel axles at the least.

Part #B37 (Idler Wheel Damper) does not

locate into the Hull, as molded in the

ESCI/ERTL/AMT model kit.. Trim and fill

this locator away - and attach the Damper

to the Suspension Arm.

While

you're at it, filling the backs of the

Drive Housings is called for in building

the ECSI/ERTL/AMT model kit Hull. Simple

pieces of styrene sheet comes in handy for

this seemingly small detail - that's easy

to miss if you get ahead of yourself -

like I do sometimes! Instead of

freehanding it, make it easy on yourself

and cut a scrap piece of paper out and

make a pencil tracing of the opening. Trim

your new template out and use it to cut

out the shape on the sheet styrene. Test

fit and trim as necessary. While

you're at it, filling the backs of the

Drive Housings is called for in building

the ECSI/ERTL/AMT model kit Hull. Simple

pieces of styrene sheet comes in handy for

this seemingly small detail - that's easy

to miss if you get ahead of yourself -

like I do sometimes! Instead of

freehanding it, make it easy on yourself

and cut a scrap piece of paper out and

make a pencil tracing of the opening. Trim

your new template out and use it to cut

out the shape on the sheet styrene. Test

fit and trim as necessary.

Circled

in the photo here are Drain Covers for the

Transmission and Engine - missing from all

the M60 series model kit Lower Hull pans.

The detail is easy to miss, unless you're

familar with the M60 series like Tankers

are. Adding it isn't difficult using

styrene sheet and your favorite scale Bolt

Heads. Circled

in the photo here are Drain Covers for the

Transmission and Engine - missing from all

the M60 series model kit Lower Hull pans.

The detail is easy to miss, unless you're

familar with the M60 series like Tankers

are. Adding it isn't difficult using

styrene sheet and your favorite scale Bolt

Heads.

Another

modification to my miniature is a revised

Driver's Hatch. Again, thanks to Joe

Daneri, I could improve my miniature's

fidelity to the actual M60 MBT by modeling

the correct Hatch. M60 MBT Driver's

Hatches were equipped with an IR Night

Periscope. The M60A1, A2 and A3 used a

newer night vision sight - appropriately

molded in the ESCI/ERTL/AMT M60A1 model

kit as I used here for this project.

In the

photo at right, the M60 MBT Hatch is

called out by caption #2. Caption #1 shows

the M60A1 passive sight equipped Driver's

Hatch. Caption #3 shows Driver's Hatches

that were modified from IR Night Vision

Periscopes to Passive Sights, with Caption

#3 from a late model CEV made from an

M60A1 Hull and Caption #4 on an M60A3 TTS

rebuilt from an M60A1. In the

photo at right, the M60 MBT Hatch is

called out by caption #2. Caption #1 shows

the M60A1 passive sight equipped Driver's

Hatch. Caption #3 shows Driver's Hatches

that were modified from IR Night Vision

Periscopes to Passive Sights, with Caption

#3 from a late model CEV made from an

M60A1 Hull and Caption #4 on an M60A3 TTS

rebuilt from an M60A1.

The

AFV Club/Academy Hatch can be improved

further by adding a little more contour

around the Periscope blister with some

putty to better represent the actual. I

used a small bit of Apoxie Sculpt for this

detail. I tried to present a photo with

enough contrast here to see the Apoxie

Sculpt worked around the IR Periscope

blister. The tan color of the bare plastic

plays havoc with the meter on my camera.

Anyway, the Apoxie Sculpt has a working

time from 1 to 3 hours - plenty of time

for this process. I worked a little string

rolled between my fingers into position

using a wet (water) paintbrush, and then

smoothed it out. If you'll notice, I did

not drill out the Driver's Hatch cast into

the ESCI/ERTL/AMT upper Hull. I used my

modified Hatch as a master to cast in

Alumilite instead. I holled out the

underside with my battery-powered Dremel

tool and slipped the new Hatch as a cap

over the original kit part. Why? No answer

other than I wanted to see if I could pull

the idea off. Never be afraid to try

unconventional approaches in modeling -

you'll always learn something new if you

do...

At

left, the TM illustrates the aluminum and

the armored versions of the later

top-loading air cleaners. Depending on the

time period and the unit your choose to

model your M60 tank - either style of side

or top-loading air cleaners would be

appropriate.

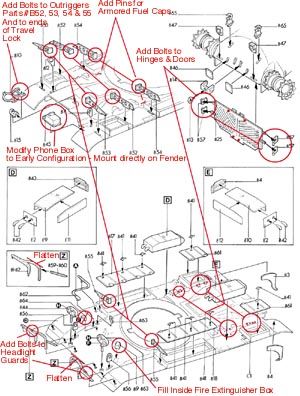

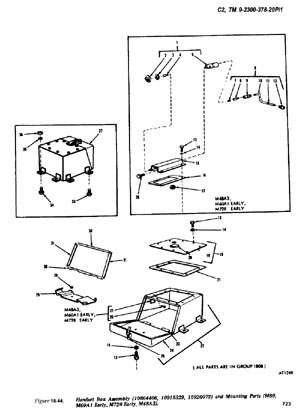

Modifying the Infantry Phone Box to the

style fitted to the M60 is easy, the

drawing at the left shows the Handset Box

Assembly as fitted to the M60, and the

difference between it and the later style

fitted to the M48A3, early M60A1 and early

M728 tanks. I sanded away the offending

detail and added my own Grandt Line #153

boltheads and a clasp from scrap solder

and foil. The Infantry Phone Box was

bolted directly to the Fender in the early

M60. Naturally, this was modified in the

field like the retrofitting of later style

Air Cleaners, and some photos of restored

vehicles show the Phone Box mounted on a

shelf. A short length of solder imitates

the cable running behind the Phone Box.

I

drilled out the mud holes in the Drive

Sprockets missing from the model kit

parts. Simple task to accomplish, I just

drilled two adjacent holes, and reamed out

the shape with a mini-file. There are

three holes each, spaced equidistant

apart. I read elsewhere on the Internet

that a modeler performing the same

conversion recommended that the Guide

Rings be eliminated on the M60 Drive

Sprockets, but I could not confirm this.

The Technical Manuals on the M60 Series of

MBT's present contradictory information

and all the photos I've seen of M60 tanks

in the fied show the Guide Rings in place.

In

my version of the ESCI/ERTL/AMT model kit,

I was missing a couple of parts for the

Drive Sprocket subassembly. I fitted

examples from AFV Club's (Academy) M48H

model kit. These fit without problem to

the ESCI/ERTL/AMT model kit.

Minor

detail additions to the Hull come in

blanking off the interior of the external

Fire Extinguisher Box mounted on the

Glacis with scrap styrene strip and very

short lengths of .022" solder to mimic the

activators. .015" solder lengths were

added as pins for the Armored Fuel Caps -

which go just about hidden in the end

result behind the Air Cleaners and

underneath the Turret rear overhang.

The

Outriggers (braces that support the

Fenders) are acceptable as presented in

the ESCI/ERTL/AMT model kit, but do

benefit from minor thinning of the tops

with a sanding stick to reduce the

thickness. Photoetch replacement parts are

too thin for replicating these parts. I

added Grandt Line #135 Bolts to the

brackets that secure the Outriggers to the

Hull to replicate missing detail in the

model kit. You'll need eight bolts per

Outrigger - 64 bolts in total. Outrigger

#1 (Front Fender) calls for two bolts to

be added on each side. I used Verlinden

resin bolts for this detail.

I

replaced the kit Headlight Units with

excellent resin examples from Grief

Accessories (#GF 025). Grief's set

includes the clear and blackout lights are

separate lenses, providing a superior

result when finished. The model kit's

Headlight Guards are also missing the

mounting brackets that are welded to the

Glacis. You can easily add this little

detail to enhance the area without a great

deal of extra effort.

The

model kit's Personnel Heater Exhaust was

improved by drilling out the end and

adding two Clamps made from lengths of

Foil and secured with Verlinden resin

bolts. The M60 has a capped port for the

xxxxx - which I made with scrap styrene

strip sanded to shape and two Verlinden

resin bolts glued to either end.

Moving

to the rear, a small length of embroidery

thread was added to the Tow Hitch pin, I

added Verlinden bolts yet again to the

Travel Lock and incorporated Grandt Line

bolts to add missing detail on the Engine

Access Doors and Hinges too. All the

Engine Grill Hinges call for added bolt

detail. You can easily add over one

hundred bolts to the ESCI/ERTL/AMT model

kit before you realize it.

Using

Academy's Poly-Vinyl Track Runs

Academy's

M48A5K model kit provides a suitable set

of poly-vinyl tracks that I chose to fit

to my miniature. I couldn't obtain a set

of AFV Club track links in time for my

project. The Academy track runs are quite

stiff though, reminiscent of the track

runs provided in Italeri's M4 Sherman and

newer LVT series Amtrack model kits.

First

off, I joined the ends of the track runs

with the traditional heated tool to

mushroom the connecting pins. This

provided a pretty strong bond. Next, I

cleaned up the seams on the end connectors

with a steel wire brush inserted into my

battery-powered Dremel tool. Next, I setup

a pot of water on the stove, heating it to

approximately 107 degrees. Using a pair of

tongs, I dipped a track run into the hot

water for a few seconds (between five and

ten). Then, I took it out of the water,

stretched and pinched the ends until it

held the shape I wanted it to be. This

method takes out warps and radical bends

old poly-vinyl tracks set into when in a

box for a long period of time. I only had

to dip the track runs a couple of times to

straighten them out and set them into a

much better shape to fit around the

ESCI/ERTL/AMT Suspension.

Very

quickly, I attached the track runs to my

model miniature, for them to cool and

setup in "shape". The fit of my Road

Wheels, Idlers and Drive Sprockets were

loose, so I wrapped short lengths of

Tamiya Masking Tape around the locator

stubs on every suspension arm. This kept

the wheels tightly attached to the model

tank's Hull. As I used Academy's Drive

Sprockets there were no problems with the

track runs fitting tightly around the

Sprocket Teeth. In the end, I saved two

hours (lt least) over what I would have by

fitting my first choice AFV Club

individual track links. The Academy

poly-vinyl track runs became quite rigid

and setup tighty as they cooled on the

model tank Hull, and would eventually only

need a tiny drop of 5-minute epoxy to coak

them down to contact the Return Rollers.

They look good in place and you can even

see a little daylight between the links -

like you would with the individual sets.

With

the tracks in place and everything else

press-fit for photography, the M60

miniature took on an agressive stance -

this was a pretty good looking tank - just

big!

How

Close Does the Miniature Measure Up to

the Real M60 MBT?

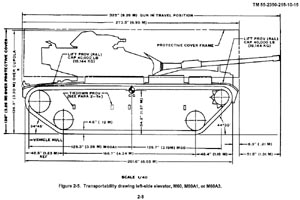

Technical

Manual 55-2350-215-10-15 provides

transportability drawings that I used to

check the overall dimensions of the

assembled model miniature - more for fun

than anything else. I had already

gleefully charged into building it and

wasn't about to go back and take it apart

again. The Technical Manual information is

useful for future projects though - who

can build just one M60 series model tank? Technical

Manual 55-2350-215-10-15 provides

transportability drawings that I used to

check the overall dimensions of the

assembled model miniature - more for fun

than anything else. I had already

gleefully charged into building it and

wasn't about to go back and take it apart

again. The Technical Manual information is

useful for future projects though - who

can build just one M60 series model tank?

The

assembled model M60 tank looks pretty nice

from all angles and that got me curious to

investigate how close it matched the real

vehicle in overall scale. The

assembled model M60 tank looks pretty nice

from all angles and that got me curious to

investigate how close it matched the real

vehicle in overall scale.

Measured

from Fender to Fender (minus the Mud Flap)

the model falls some four scale inches

short (3mm) of the posted 273.5 inch

length. In comparing the rest of the model

Hull dimensions, the measurement from the

centerline of the Drive Sprocket to the

centerline of Road Wheel #6 falls some 3.5

inches short in scale as well. The Angle

of Departure and Angle of Approach do come

very close to the TM drawings and the

distance between the Idler Wheel and Road

Wheel #1 matches.

The

TM drawings suggest that the Hull length

is 257 inches - which the ESCI/ERTL/AMT

Hull matches in scale. To correct the

distance between the Drive Sprocket and

Road Wheel #6, and maintain the proper

spacing between the rest of the Road

Wheels and Idler and Return Rollers, would

call for more work than most would

consider warranted to gain a couple of

millimeters. The model kit's basic

assembly looks very nice and the shortage

is not very noticable in the final

product.

Vertically,

the ESCI/ERTL/AMT model comes out better.

The Hull sits above the posted Ground

Clearance of 14 inches - by a couple of

scale inches. The overall height, measured

from ground to the top of the Sight

Housing on the Commander's Cupola is 126.3

inches - which my finished miniature

matched despite using an aftermarket

Turret and Cupola from another model kit.

Ground

to top of Bustle Stowage Rack at 98.6

inches matched, Ground to top of Return

Roller/Bottom of upper track run at 54.2

inches matched, Ground to top of Fender

Stowage Bins at 69.1 inches and Ground to

top of Air Cleaner (side-loading) at 72.2

inches matched as well in miniature.

The

model miniature's width matches up with

the TM drawings, with a scale overall

width of 143 inches, Road Wheel track

(outer wheel edge to outer wheel edge) of

130 inches and Track center to Track

center of 115 inches. The Academy

poly-vinyl track runs I fitted to my

miniature are narrower than the 28 inch

track span posted in the drawing by 2

scale inches, but still slightly extend

beyond the Fenders when attached to the

model. Though they look fine once in

place, this isn't in strict fidelity to

the real tank. All in all, the measurement

exercise was fun and I didn't feel

compelled to mess around with the Road

Wheels, Drivers and Track width this time

around. The model kit captures the look

and feel of the M60 MBT quite nicely for

what I was seeking in modeling the

subject.

|