|

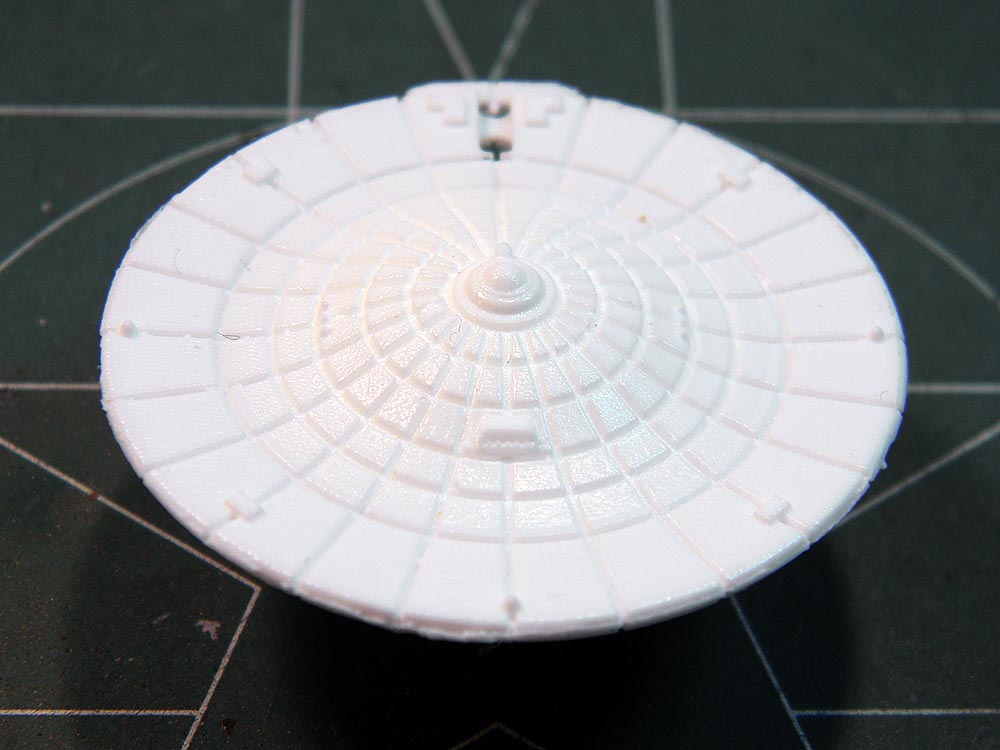

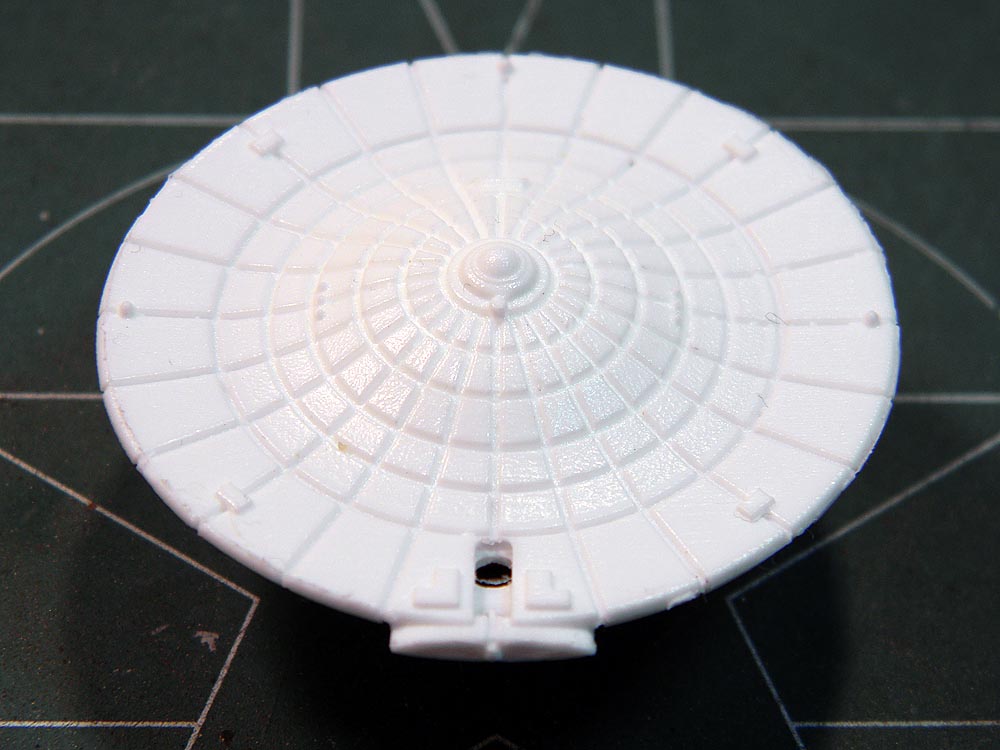

The primary hull in my

Squadron Box was well-done and relatively

free of blemishes and excess casting flash.

The first thing that struck me about these

new miniatures is the softness of the resin

- it will bend and give with rough handling.

It has a hardness like soap, and a sharp

knife can actually hurt you here more than a

used knife, as it will cut deep into the

material without much effort. Here, I had to

clean up the seams around the saucer's edge

and dig out some of the rubber mold that was

embedded in one of the Impulse Engine

exhausts. Of all the parts for the ships in

Squadron Box #1, this was the best-looking

of them all.

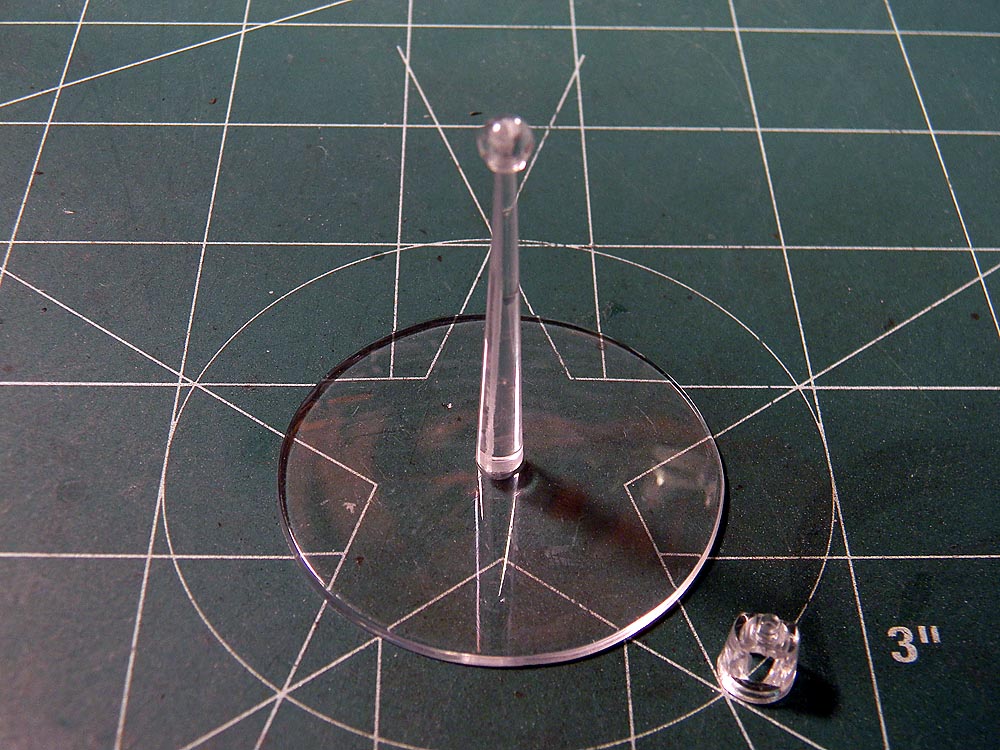

Above, the Stand that comes

with these miniatures allows for posing the

piece in exciting stances. The clear "hat"

is placed over the "ball" on the Stand to

allow for positioning. The "hat" is glued to

the bottom of the miniature starship, and

allows the owner to remove the ship from the

Stand for easier transport or storage. The

base of the Stand is two inches in diameter,

more than enough to ensure the lightweight

miniature has a secure footprint, and if

left clear can be used with a hex map system

as distances between ships are measured from

center of the stand to the opposing stand.

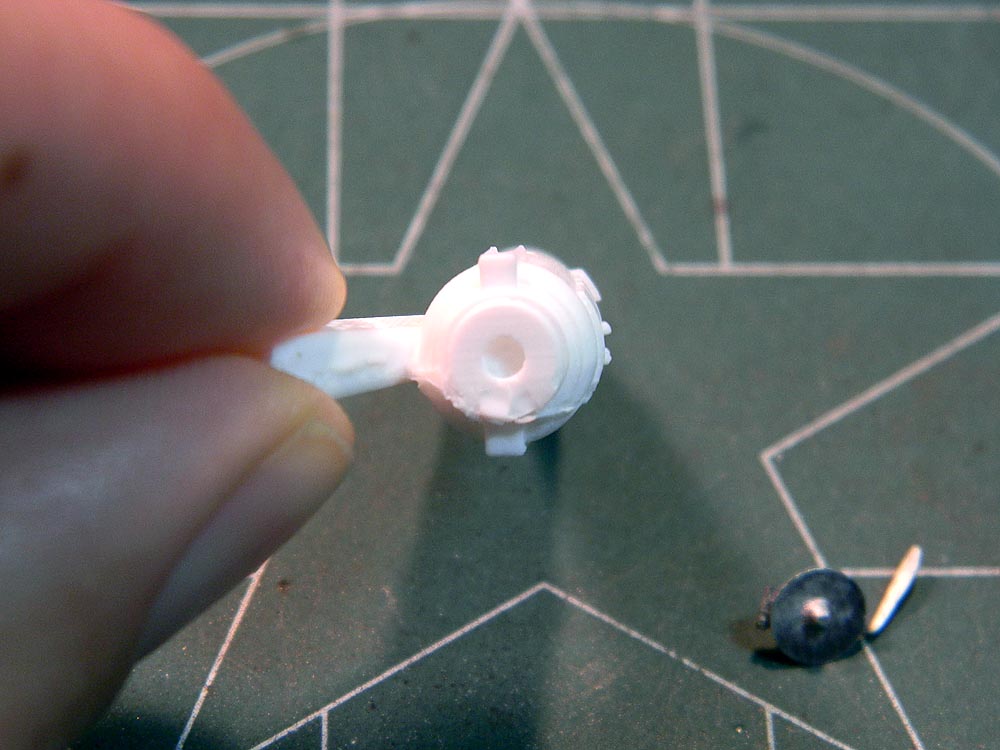

Clean up on the Secondary

Hull took some time and forethought. Above,

the mold seam left over from the pour mars

the Deflector Dish housing and proves

difficult to remove and keep it round.

Below, the mold separation goes behind the

Neck and I was left with some filling here

as well as reshaping. The Deflector Dish is

a white metal piece that slips into the

housing, just a quick clean up of the hole

is called for. I cleaned up the white metal

casting with a fine sanding stick to improve

the finish.

The Secondary Hull is

further marred by the placement of a pour

plug right over the Hangar Bay Doors -

completely obliterating the detail intended

for this area. Below, the mold parting seam

on the back of the Neck, and area calling

for filling and shaping. This mold seam ran

down the starboard side of the hull, just

right of the Strongback detail. My part was

slightly shifted in the mold, so the step

between right and left halves was pronounced

here and had to be addressed. I wound up

removing detail on the Neck during clean up

that I replaced with a length of styrene

strip - the Strongback detail that extends

up the Neck towards the Impulse Engines.

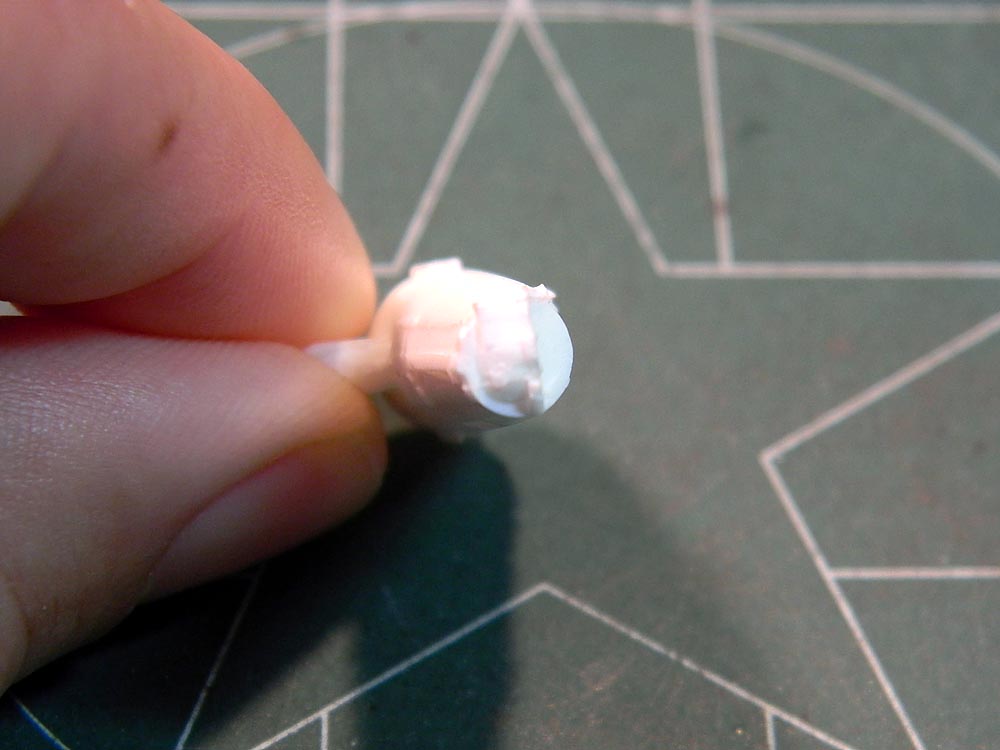

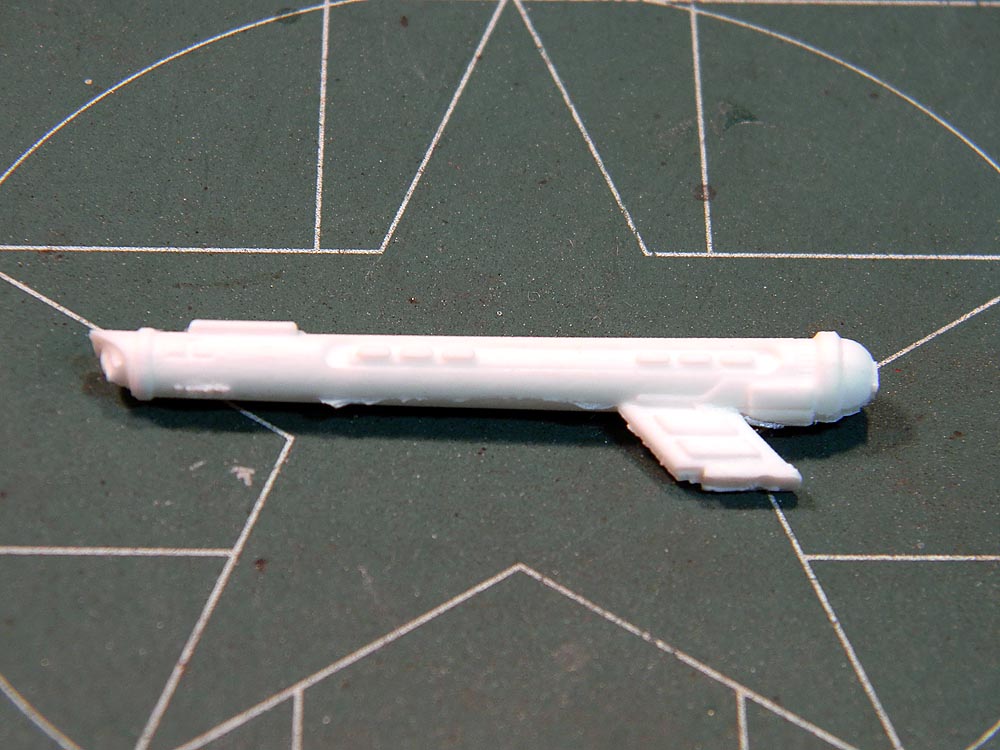

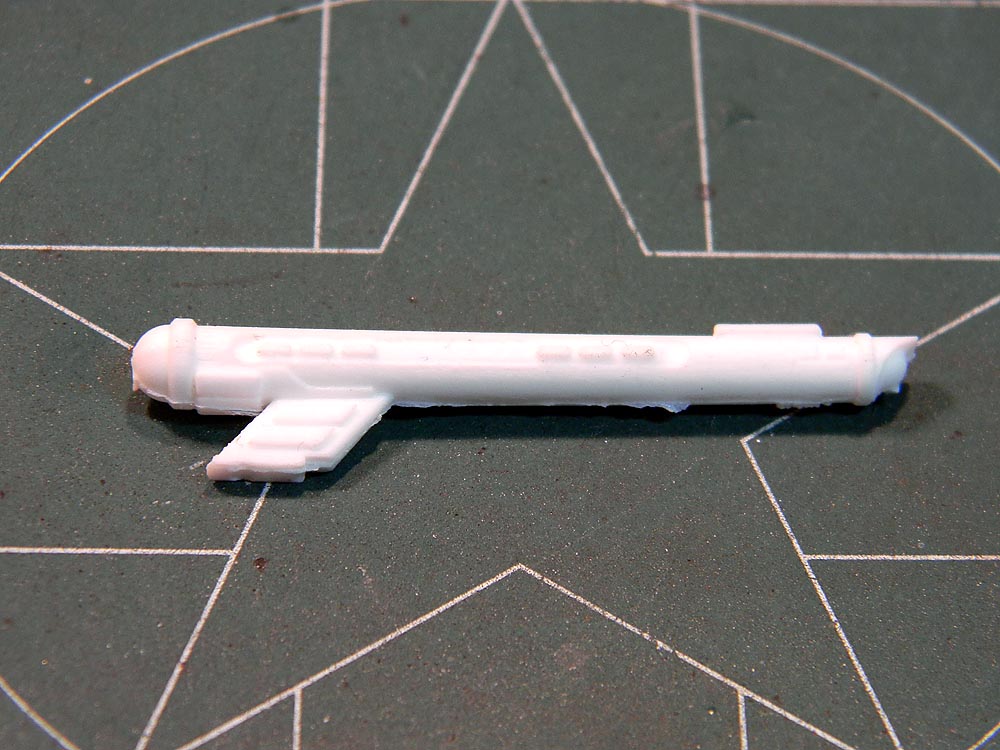

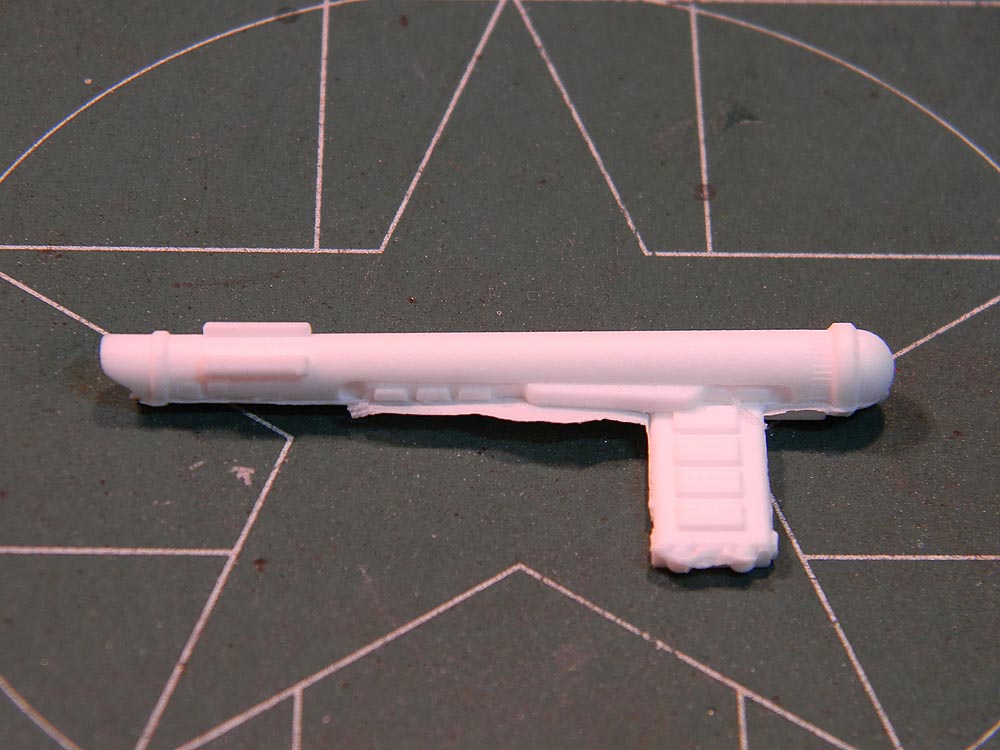

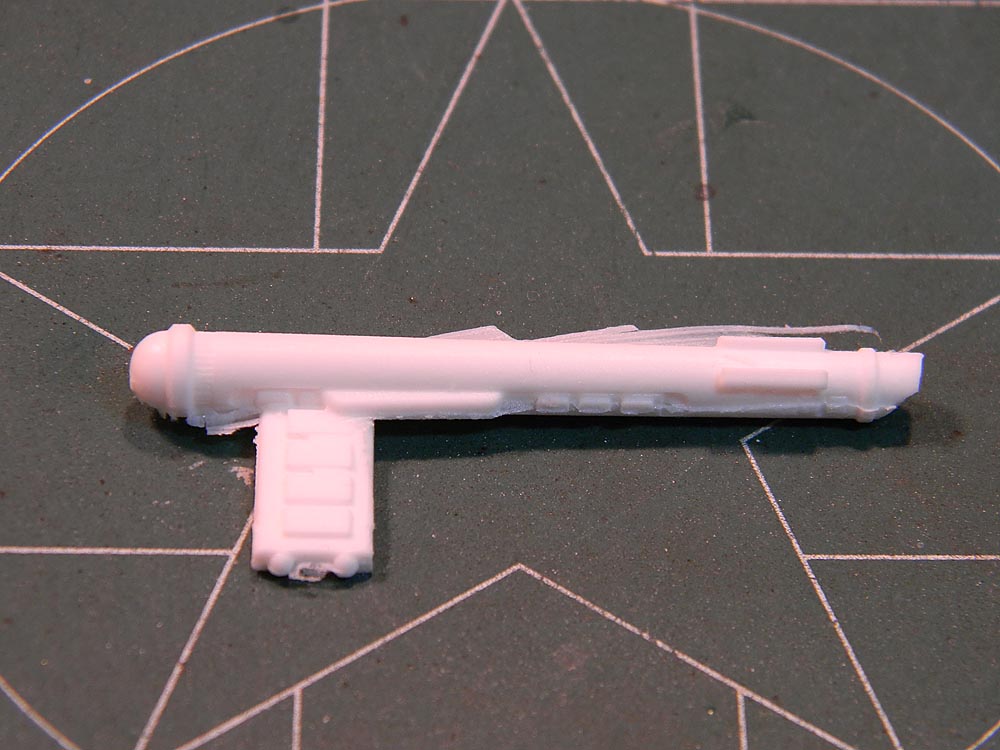

Above and Below, the Center

War Nacelle isn't bad, it proved to be easy

to clean up and did not warp during the

process. The pour gates on the end caps of

the Warp Nacelle caused a little challenge

to clean up and maintain a round profile.

Like the Center Warp

Nacelle, the outboard Warp Engines called

for patient clean up on the end caps, and

suffered from slight mold shift. In an

attempt to keep as round a profile as

possible, I used putty in the worst spots as

a filler. The way mold parts causes excess

flash that endangers detail during the clean

up process. Both of these castings were a

little soft, like the resin had not

completely cured, and I proceeded slowly so

as not to warp them during with clean up

activity. Neither are perfectly round, but

close enough so as not to detract from the

overall miniature.

A few hours later, I placed

the Dreadnought Cruiser on a Gamescience

Stand in preparation for priming and

finishing. Yes, it does fit without

modification onto the Gamescience Stand, and

is quite secure due to its low weight. I

like the way it looks on the Gamescience

Stand and it is nice to have an alternate

option for mounting it..

I assembled the miniature

by first inserting the Center Warp Nacelle

into position on the Primary Hull. The

locating notch and bottom of the Nacelle's

Pylon must be cleaned up neatly - as the fit

is precise here when you insert the

Neck/Secondary Hull from below. I only

needed to use gap-filling superglue here to

bond the parts together. With the Center

Warp Nacelle, Primary Hull and

Neck/Secondary Hull properly aligned and set

with a little drop of superglue accelerator,

I then set the starboard outrigger Warp

Nacelle in place. Checking the alignment

before setting in place with a drop of

accelerator, I finished by placing the port

Warp Nacelle in place. All in all, perhaps

five minutes or so from start to insertion

of the Deflector Dish.

|

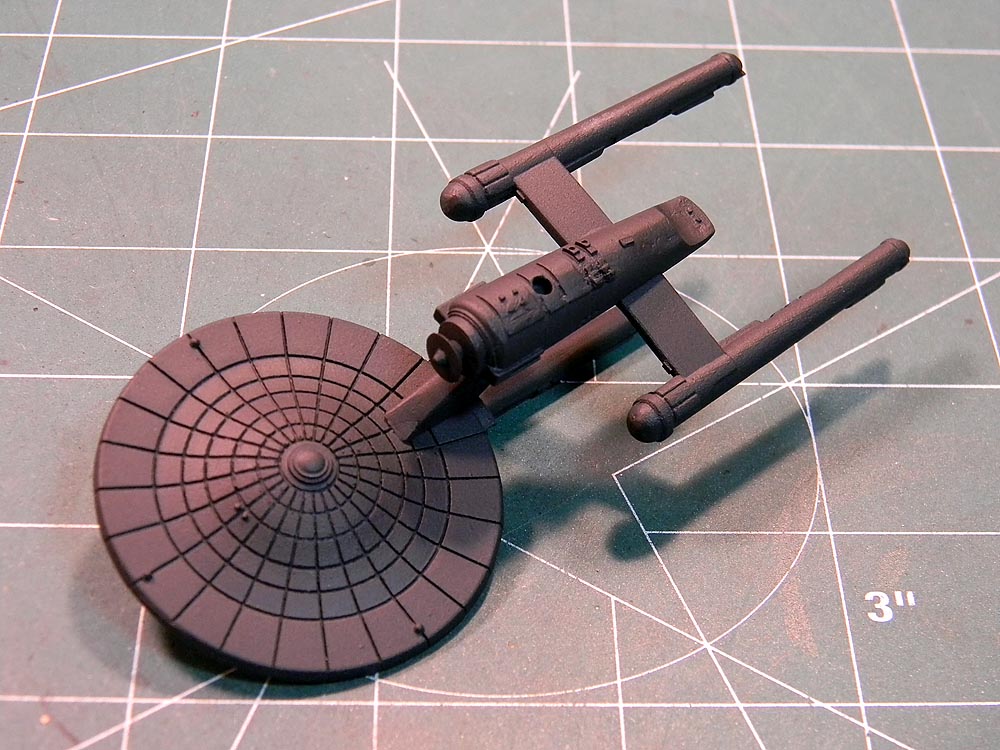

The

putty work on the underside of the

Dreadnought Cruiser, location of the worse

mold shifting and clean up. It was just a

nasty task, and took some time not to

obliterate all the detail here. In both

photos you can see the forward left tip of

the Neck is missing on my example. I thought

maybe it had broken off during shipment, but

I couldn't find it in its ziploc bag. In the

bottom most photo, I build a putty fillet to

replace this detail, not yet sanded smooth

in this picture.

The bright white resin

plays havoc with the camera, and your eyes,

during assembly and clean up. When you get a

coat of primer paint on it, however, the

detail on the miniature pops out at you - as

do the flaws. All of your effort in

puttying, repair and filling will reward

you. It is difficult to see every flaw in

the bare white resin before you prime it

with paint, so don't be surprised when you

find some spots to address when you put

paint to the mini. The bright white resin

plays havoc with the camera, and your eyes,

during assembly and clean up. When you get a

coat of primer paint on it, however, the

detail on the miniature pops out at you - as

do the flaws. All of your effort in

puttying, repair and filling will reward

you. It is difficult to see every flaw in

the bare white resin before you prime it

with paint, so don't be surprised when you

find some spots to address when you put

paint to the mini.

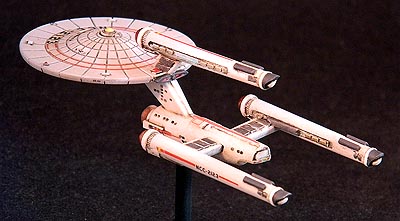

When it came to

applying the color coat, I airbrushed Model

Master Acryl #4763 Flat Gull Gray and then

applied a thin top coat of #4769 Flat White

in a fine, cloud pattern, taking advantage

of the deeply engraved and raised details on

the miniature. With the larger size it's

easier to airbrush some weathering effects

by varying the tone of the finish. I picked

out all of the smaller details with the same

Vallejo Acrylics that I use on the smaller

Starline 2400 gaming miniatures. Because

there is more details to pick out - it takes

longer to paint - but the result makes up

for it. The Starline 2500 mini comes to life

as you pull the details out with careful

painting.

A little hesitant to

apply an overall wash with the deeply

(overly for my tastes) engraved Deflector

Grid detail on the saucer, I thinned down an

AK Interactive Dark Brown for Green Vehicles

enamel pin wash. I avoided enhancing the

Deflector Grid lines any more than they

already were after the airbrushing, but did

flow a highly thinned mixture over them to

bring the whole area into harmony with the

rest of the weathering on the miniature.

Taking no chances with the wash, I let it

setup for 30 minutes and gently removed the

excess. Once satisfied, I then coated the

miniature with Polly Scale Satin for later

decaling.

Despite the rough

surface detail, which I think is an artifact

of the CAD "growing" process, the Starline

2500 miniature comes to life when you start

picking out details. The larger size and

abundance of raised detailing makes this an

easier proposition, and as you proceed,

you'll find yourself moving along faster and

faster - kinda a fun rush to the finish

line. Despite its problems and warts, a fan

of SFU gaming miniatures will certainly love

the end result. From the casual viewing

distance on a game table, these Starline

2500 miniatures look great.

The Federation Missile

Dreadnought's locating hole for the Stand is

already a diameter that will also

accommodate the Gamescience Stand shown

here. I decided to use it after plugging the

relatively tiny Burke-class Frigate onto the

Mongoose supplied Stand. The "hat" is nearly

half as big as the Burke-class Frigate

itself - and breaks up the impression the

mini makes when viewed on the table. So, I

decided to use Gamescience Stands for my

first five Starline 2500 minis.

Below, the set of

custom decals created by Tenneshington Decals

applied to the miniature. I also ordered a

set of Combat Leader Rings for the saucer,

as i really like this look. I intend for all

my Federation starships in the Starline 2500

line to be marked with the Combat Leader

Rings.

|